Polymers and other high performance materials

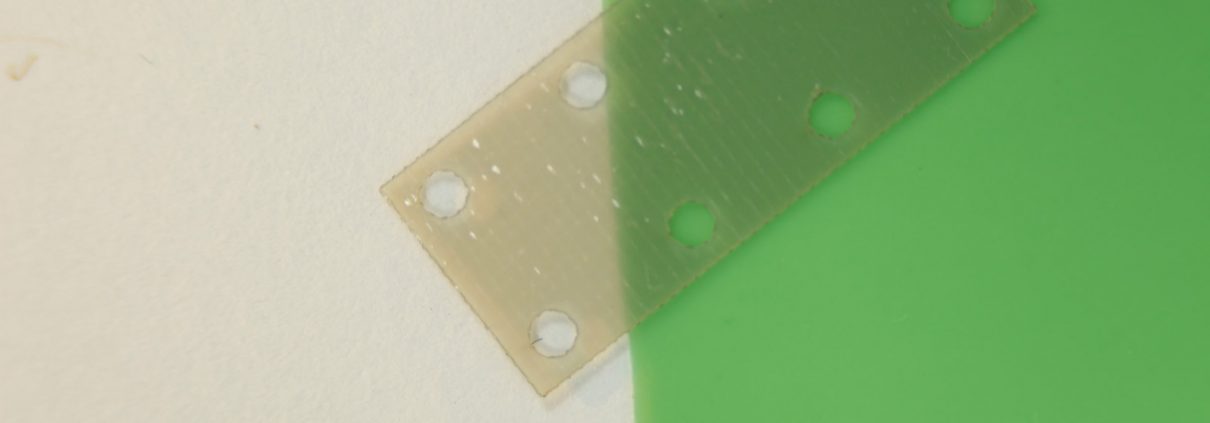

Most polymers are excellent candidates for our laser equipment – whether b-stage epoxy (shown above) or silicone rubber. FR4, duroids, as well as PTFE composites are examples . Eccosorb and other metal loaded rubbers are used in high frequency circuit environments. See more examples of these parts here.

We laser cut these materials in a wide range of thicknesses, .001″ (.025mm) to .125″ (3mm) for example. Laser cutting is a good alternative to die cutting or molding. Woven polymers are bonded at the cut edge thereby reducing fray.

Laser is well suited to prototype volumes as well as high production. Learn more about these popular materials from this link.