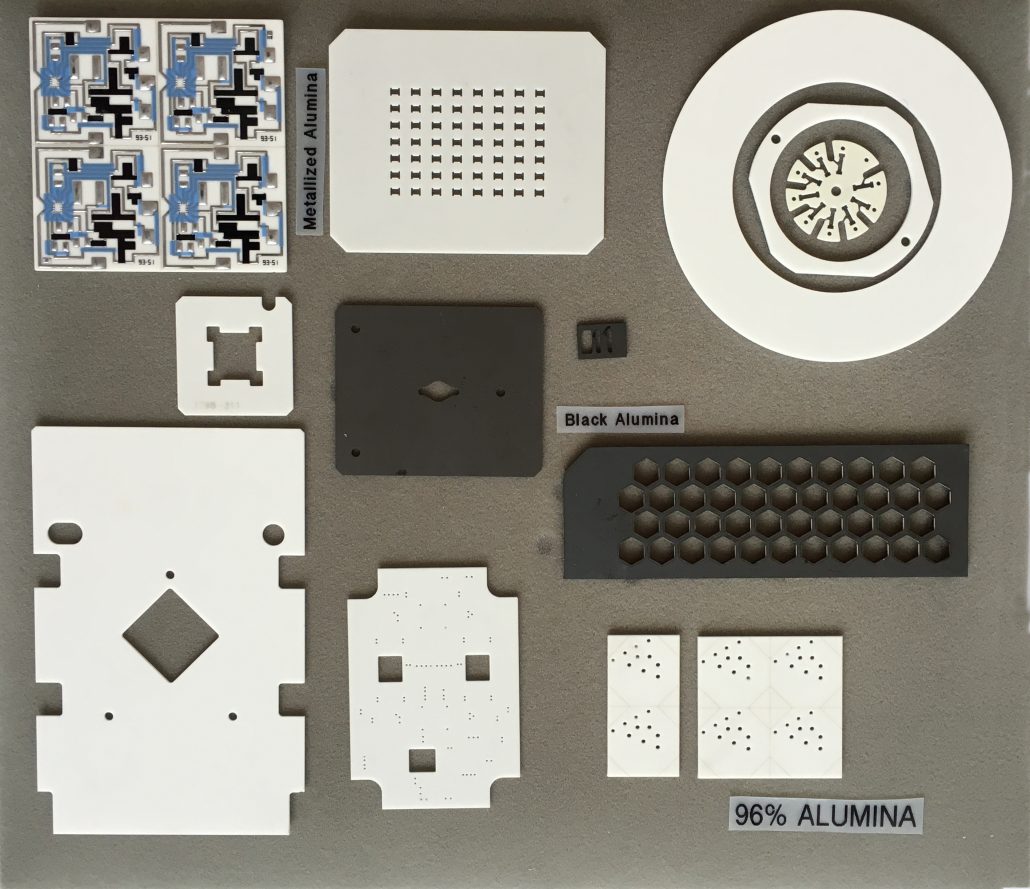

Ceramics

Our lasers easily machine extremely hard materials such as Alumina and other Ceramics into complex shapes. These shapes can have through cut features for access. Through cuts allow front to back electrical connections as well. Ceramics are often used in applications requiring good thermal conductivity and or very good dimensional stability. Ceramics are great for high reliability applications such as military and defense. 99% pure alumina often used for thin film high frequency circuitry and 96% aluminas are often used in thick film applications. Ceramics are used in medical and communication devices.

Accu-Tech’s laser workstations have software and hardware for optically aligning to existing metalized patterns. The lasers often singulate individual circuits from an array. Machining and scribing is used for separation. Very small parts can be produced, two or three millimeters for example.

Ceramics have excellent abrasion resistance. As a result, they make durable spacers and small part locators. We stock a variety of commonly used sizes for quick turn around.